OUR CLIENTS ARE OUR PARTNERS

From the draft to the final delivery of the die, we create, improve, implement and certify both our own and third party designs.

Our priority is to guarantee the backing and support in all moments, while we attend our partners in all phases of the project with the goal of reaching excellence in quality, price and time invested in the die.

STUDY

PROJECT

CONSTRUCTION

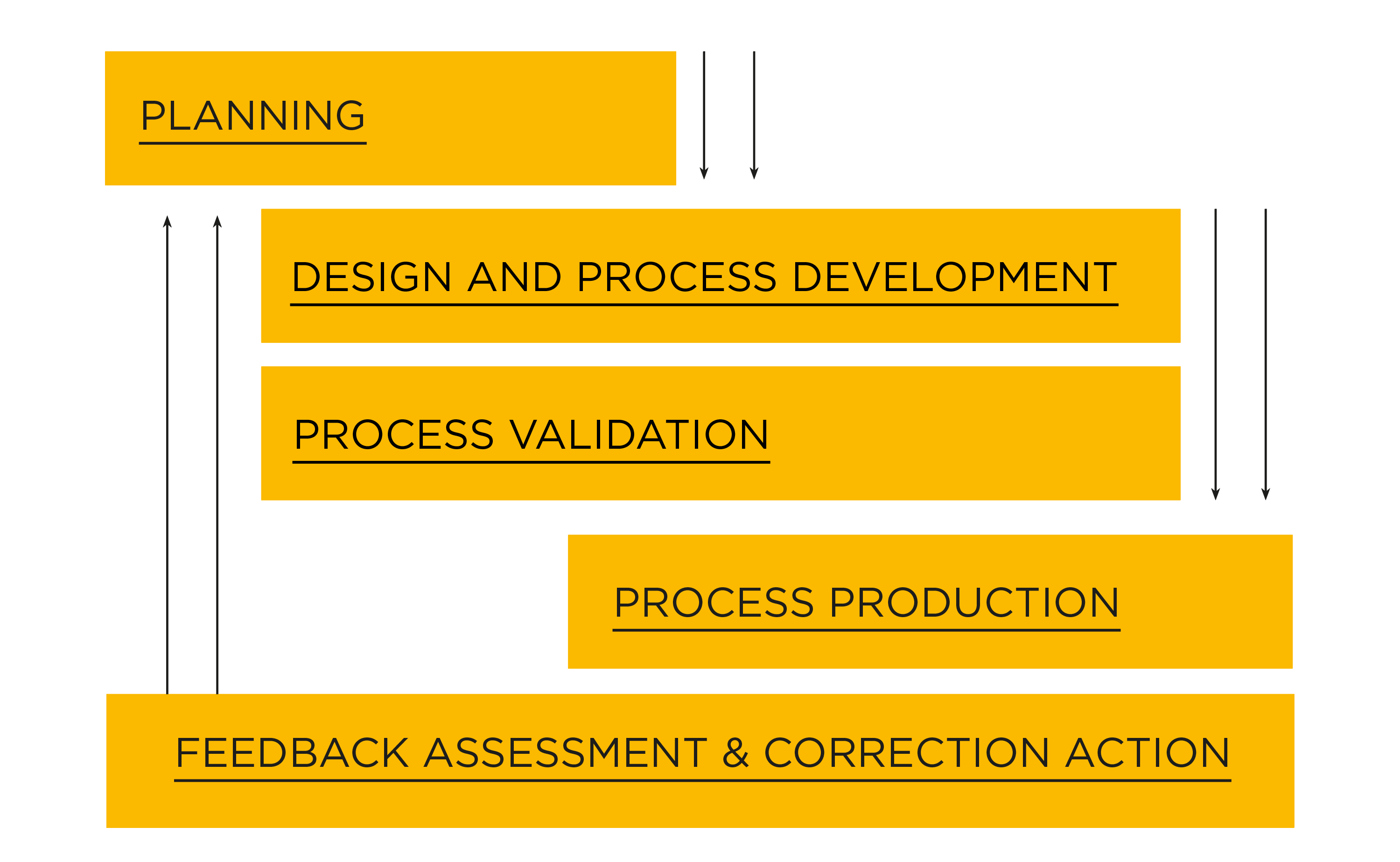

Our engineering and R&D&I department is capable of organizing, executing and supervising the management of the project under the APQP protocol.

This is thanks to the CAE simulation equipment ran with Dynatron, the management of tooling with Climatrón and 3D design with the Catia software.

During the process, we highlight the points to improve and implement solutions during the phases of prototype, development, testing and validation.

This way we make sure that the dies created meet the homologated quality standards and are certified to enter the production chain.

APQP

ADVANCED PRODUCT QUALITY PLANNING